5 Frequent Questions about our WECS (and their answers)

Warehouse Execution and Control Systems (WECS) are nothing new in the warehousing industry, though the terminology may be new to some. A WECS can package together functions that have been available from Warehouse Control System suppliers for many years. In this article, we’ll cover some of the FAQs about Warehouse Execution & Control Systems, and determine how WECS can support your operations.

Definitions: What are WMS, WCS and WECS?

In the field of warehousing, there are now so many acronyms assigned to the different software systems available that things can be difficult to follow. To help you understand this shorthand and how the functionality of each system fits together, here are some brief definitions of WMS, WCS and WECS.

Put simply, a WMS keeps track of inventory in the distribution centre. It knows what is there, what’s coming in and what’s going out, and can sort this information into task lists. However, a WMS does not track the exact location of materials within the warehouse.

On the other hand, a WCS manages the material flows within the warehouse, controlling machinery to create efficiency and relaying information about each item’s location to the WMS.

A WECS does the same as a WCS, with added capabilities for synchronising and directing labour tasks. It interfaces with the WMS to ensure optimum efficiency.

Warehouse Management System (WMS)

A WMS is a Transactional Software that tracks, analyzes and coordinates inventory, orders and customers, combining data from these sources to direct order fulfilment processes. WMS software may also have reporting capabilities to create documents for data analysis.

This type of software can manage and assign conventional handling tasks, such as:

- Delivery Receipt and Put-Away

- Replenishing Pickface

- Batching or waving for picking

Warehouse Control System (WCS)

A WCS is an Operational Software that connects and communicates with automated systems to support the efficient flow of materials through a facility. By triggering the equipment’s programmable logic controllers (PLCs), a WCS can relay information with automated equipment including:

- Sorters

- Conveyors

- Automated Storage and Retrieval Systems (AS/RS)

- Voice- and Light-Directed Picking Systems

Warehouse Execution & Control System (WECS)

This Performance Optimization Software includes and expands the functionality of a WCS and integrates with a WMS. The WECS uses sophisticated algorithms to leverage real-time inputs from all automation, such as:

- order finishing and manifesting

- integrating data from inventory, transportation, operatives and orders

This can help distribution centres to optimise fulfilment operations through end-to-end, dynamic management.

A typical WECS is available as a packaged, modular software solution that is versatile and adaptable to any setting that uses automation. During installation, users can configure different options to create functions as needed, without costly software customisation.

Choose a Warehouse Execution and Control System that integrates with prominent commercial WMS brands so that you can approach installation without difficulty. An ideal WECS will also be able to interface with any semi- or fully-automated equipment and material handling systems.

By leveraging data through connected material handling systems, a WECS can help businesses optimise processes with an overview of all parts of the system.

1: What Can a WECS Do?

1: What Can a WECS Do?

Using information from both WMS and automated equipment, the WES orchestrates operations to deftly tackle today’s high-level fulfilment challenges. There are many functions a WECS can perform, supporting efficient and smooth-flowing warehouse operations at all times. A robust WECS can:

- Examine order data from the WMS to continuously prioritise and sequence workloads across all the automation in a facility. This reduces delays and keeps operators and equipment working at a steady, continuous flow throughout all processes, including receiving, replenishment, picking, conveying, sorting, packing, order finishing and shipping.

- Integrate with all material-handling systems throughout the facility, whether they are conventional, semi-automated or automated. This enables coordination and continuous reallocation of work against available capacity, equipment status and actual resource availability.

- Support fluid unloading of inbound inventory. The WECS automatically checks in and reconciles receipts against advance shipping notices (ASNs), or blind receipts acknowledged as either purchase order (PO) or stock-keeping unit (SKU) items with camera-based data entry.

- Optimise the release of orders to accommodate compressed cycle times and the order variety common to omnichannel fulfilment operations for picking, packing, value-added service operations, and order finishing of cartons and/or bags prior to shipment.

- Quickly apply complex sorting algorithms to balance and optimise order building at sort locations and/or chutes in real-time for loop sorter and put wall users.

- Optimise inventory selection or picking, whether from manual picking areas or automated storage and retrieval systems (AS/RS). This can include shuttle and crane-based equipment, vertical lift modules (VLMs), and/or horizontal and vertical carousels to maintain a balanced material flow. Additionally, storage systems can be used for staging and automatic release of tasks between workflow areas.

- Integrate and manage highly specialised automated order finishing equipment, including auto-boxing and auto-bagging of outbound products, automatic print-and-apply labelling, custom packing list printing and insertion, and collateral insertion.

- Automatically identify, weigh, measure and sort outbound orders based on predetermined algorithms and freight optimisation specifications. The system automatically verifies the product at the docks, nimbly manifests it and loads it onto a trailer.

- Maximise uptime by identifying anomalies in performance and detecting trends in automated equipment use. This information can be used to signal potential failures or prompt users to proactively schedule preventive maintenance, reducing the risk of damage and costly repairs.

- Interface with or manage autonomous mobile robot (AMR) fleets to enhance labour for goods-to-person picking, sorting, and material movement applications.

With so many potential functions, a WECS can be a game-changer for warehouse material flows and data handling, supporting efficiency and optimisation in all areas.

2. With What Types of Automated Equipment Does a WECS Interface?

The ideal WECS includes WCS functionality to integrate with the control technologies of a variety of automated material handling equipment and ancillary technologies. Our NEXUS WECS is compatible with many control technologies, making it ideal for integrating into current systems. Typically, WECS software interfaces directly to the machine controls of equipment such as:

- Conveyors: Accumulation, belt and live roller.

- Sorters: Loop sorters (bomb bay, cross belt, tilt-tray), rope-based garment on hanger (GOH), pop-up wheel, shoe, swivel wheel, tilt-tray, multi- and split-belt, swing arm/bat, transfers, and more.

- Induction Merges: High-speed servo and variable frequency drive (VFD), slug build and release, inverters, saw-tooth, case, singulators and gap optimisers.

- Automated Fulfilment and Picking Systems: Pick-to-light, put-to-light, put-walls, pack-to-light, picking carts and other paperless picking, kitting, assembly and sortation systems. Typically, this functionality is integrated within the WECS, however, external interfaces are also supported.

- Robotics: Autonomous mobile robots (AMRs), robotic arms, and goods-to-person picking systems.

- Automated Storage & Handling Systems: Automatic guided vehicles (AGVs); automated storage and retrieval systems (AS/RS); horizontal and vertical carousels; vertical lift modules (VLMs); fluid loaders and unloaders; robotic and conventional palletizers and de-palletizers; and trolley-based garment on rail systems. Typically, the automated storage system manages its inventory at a micro level, while the WECS manages inventory at a macro level (everything within the facility).

- Order Finishing Systems: Product bagging and boxing; print-and-apply labelling; and document insertion of catalogues, coupons, special offers, shipping information or other customer-specific materials.

- Automatic Identification and Data Capture (AIDC) Technologies: Vision, scanners, dimensioners, check weighers, marking and coding systems. Typically, the WECS interfaces to an external controller (usually PLC-based) that is utilised to coordinate data and container movement on the material handling equipment.

3. What Types of Processes can a WECS Enable?

By integrating the WMS’ higher-level order fulfilment view and the WCS’ intelligence on actual operational function, utilisation and status, a WECS can automate and optimise various processes and tasks without human intervention, and in real time. These include:

- Reallocation and redistribution of work to prevent bottlenecks

- Automatic triggering of pick-face replenishment, prompted by real-time updates of inventory from the WMS

- Release of orders in a continuous flow

- Execution of cycle count triggers within conventional and automated storage systems

- Automated exception management and diagnostic tools

- Comprehensive views of workflows in a dashboard, with individual status and location by handling unit, wave or batch

- Ensuring a high degree of accuracy in item and parcel routing, identification and manifesting

- Continuous measurement and reporting of all key operations metrics

- Delivery of business intelligence and key performance indicator (KPI) analysis via dashboards

- Up-to-the-second graphic visibility into equipment status/performance

- Anticipation of shortages or maintenance needs through predictive analysis, correlating inventory and equipment status

- Management of AMR fleets

These processes are key to optimal warehouse material flows. A WECS provides data-led, fully integrated automation of all these tasks to keep your warehouse running at optimum speeds.

4. What Industries will benefit most from a WECS?

The enhanced operational visibility delivered by a WECS can provide timely, accurate optimisation for many different businesses. The greatest benefit will be seen by:

- Distribution centres that use multiple types of automation

- E-commerce retailers for both consumer and industrial products

- Third-party logistics (3PL) service providers

- Omni-channel fulfilment operations serving e-commerce customers, retail store replenishment and wholesalers

- Operations struggling to keep up with higher order volumes and rapid processing of thousands of small, one- and two-line orders

- Manufacturers that maintain and receive component parts inventory for just-in-time lineside delivery

- Micro Fulfillment

- Reverse Logistics (Returns)

The final two types of operations that we would like to highlight here benefit from the WECS in unique ways, which are explained below.

- Facilities with Lean initiatives: dynamic sequencing and induction of work by the WECS supports flexible order prioritisation that is based on service-level demands and labour accessibility

- Operations prone to out-of-balance workflows: The WECS uses real-time monitoring of in-process tasks to redistribute work “on the fly” from an overtaxed area to an underutilised one.

5. How will NEXUS WECS benefit my operation?

Guidance Automation’s NEXUS WECS can synchronise and streamline complex operations — particularly those in high throughput, sophisticated order fulfilment facilities serving omnichannel and direct-to-consumer retailers.

In this section, we explain how NEXUS works.

- NEXUS WECS uses algorithms to receive and process orders, translating inputs across from an operation’s existing information systems, including WMS and enterprise resource planning (ERP) systems.

- It then synchronises and directs multiple, disparate automation technologies using an integrated WCS for material handling equipment (MHE).

- The result is:

- cohesive system management

- balanced continuous workflows

- coordinated control of different systems to enhance order flow, accuracy and fulfilment speed.

Utilising integral, real-time decision engines embedded within the NEXUS WECS software and controls, the system optimises automated processes, such as product flow, storage, retrieval, picking, sorting (including put walls and loop sorters), order processing, packaging, packing slip printing/inserting, shipment labelling and shipment of inventory. It then intelligently integrates those processes at all points within an operation.

Because NEXUS WECS removes silos of data and automation, it is ideal for multichannel order fulfilment operations that require advanced organisation across disparate technologies in order to accomplish complex order distribution processes.

With a proven history of interfacing with virtually every commercially popular WMS and ERP brand, NEXUS WECS has successfully supported operations utilising:

- Manhattan

- Körber

- JDA

- Oracle

- SAP

- Softeon

- Infor

- and custom, home-grown and other systems.

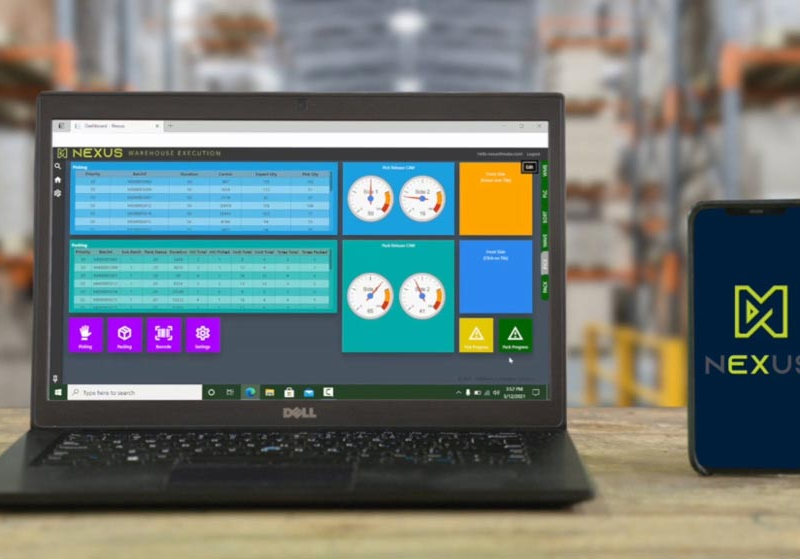

NEXUS WECS incorporates direct control functionality to optimise efficiency and performance across a broad range of material handling automation and order-finishing systems. Further, NEXUS WECS provides managers and supervisors with in-depth dashboards that offer valuable, real-time visibility into critical operations and key performance indicator (KPI) data.

Guidance Automation Solutions for Material Handling

Small to medium businesses trust Guidance Automation as the provider of automation solutions, because we offer expertise and support to unlock the potential of automation for all.

We have been developing automation solutions, knowledge and experience for 30 years, and our technologies are now facilitating smarter working in warehouses, distribution, fulfilment/e-commerce, manufacturing and healthcare facilities.

We offer Industry 4.0 solutions that are tailored to each individual organisation, providing the benefits of an adaptable, versatile service. At Guidance Automation we have access to certain technologies which can build efficiency and resilience in your business, including NEXUS Warehouse Execution & Control System. Our goal is to provide support for implementation, ongoing optimisation, modification, servicing and maintenance, making automation accessible for businesses of any size.

NEXUS WECS can streamline managing your automated equipment, creating efficient workflows and integrating with existing software. View all the data from across the facility on a visual dashboard, with the easiest implementation available.

To get started, speak to a Warehouse Execution & Control Systems Expert at Guidance Automation.

1: What Can a WECS Do?

1: What Can a WECS Do?