5 Key Lessons from the Global Industrial Robotics Survey

The 2022 McKinsey Global Industrial Robotics Survey is a deep dive into industrial companies’ previous and planned spending on robotics and automation. Conducted in September 2022, the findings confirm that industrial robotics is going to grow rapidly on the global stage. This survey goes deeper than this, offering key insights into the industries that will drive growth, perceived barriers to automation and the most anticipated benefits.

Generally speaking, the survey confirmed that companies in all sectors are planning to increase investments in robotics and automation over the next five years. Automated systems account for 25% of planned capital spending before 2027, and this trend has already begun, with companies in North America purchasing 24% more robots between January and September 2022 than in the same period in 2021.

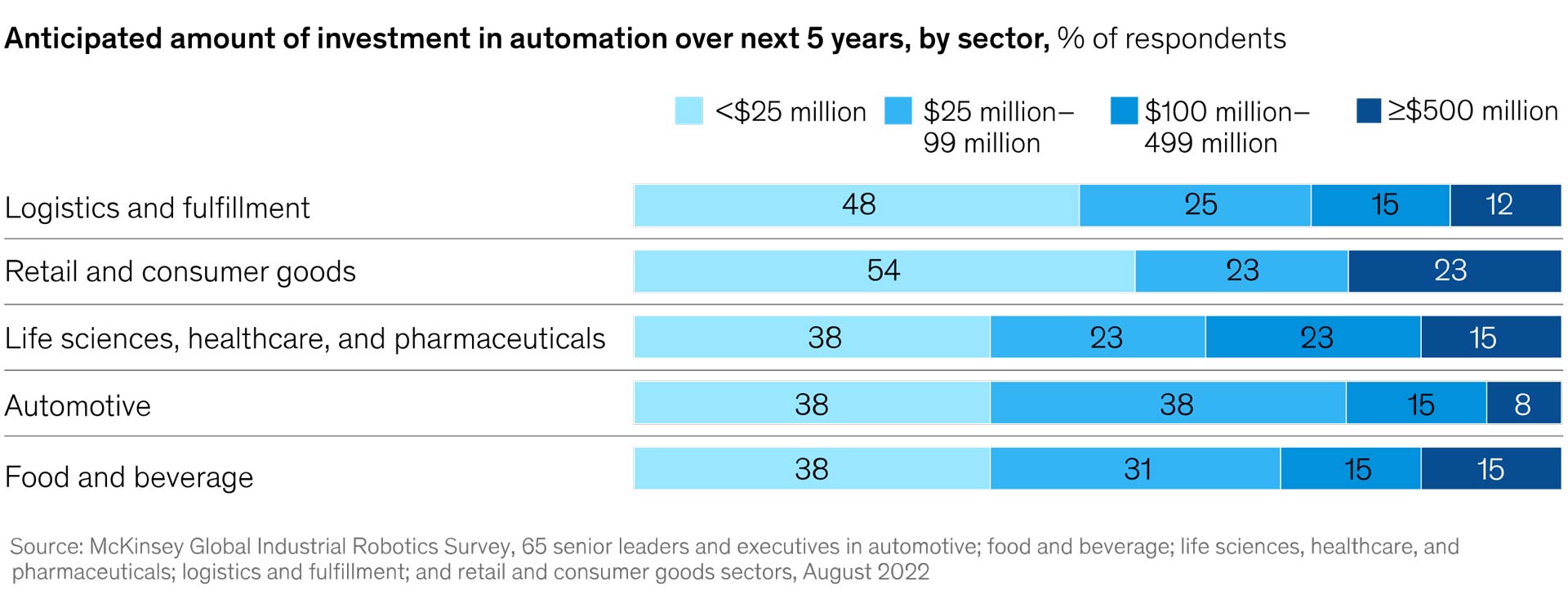

1. The Biggest Spenders: Retail and Consumer Goods and Life Sciences, Healthcare and Pharmaceuticals

Of the sectors surveyed, Retail and Consumer Goods companies project the highest investments in automation and robotics over the next five years. 23% of respondents in the sector plan to spend more than $500 million, generating a huge amount of growth in the market.

When we combine the top spending brackets, we can see that 38% of respondents in the Life Sciences, healthcare and pharmaceuticals sector plan to spend over $100 million. This may be because collaborative robots (co-bots) can be helpful in manufacturing pharmaceuticals and medical devices because they can be sterilised easily.

Retail and Consumer warehousing, logistics and eCommerce fulfilment can all benefit from automation with robotic material handling equipment. Moving conveyance from belts or rollers to Autonomous Mobile Robots (AMRs) can make your internal systems more flexible and save huge amounts of space. For businesses in the retail and consumer sector, this can be a good place to start when investing in robotics.

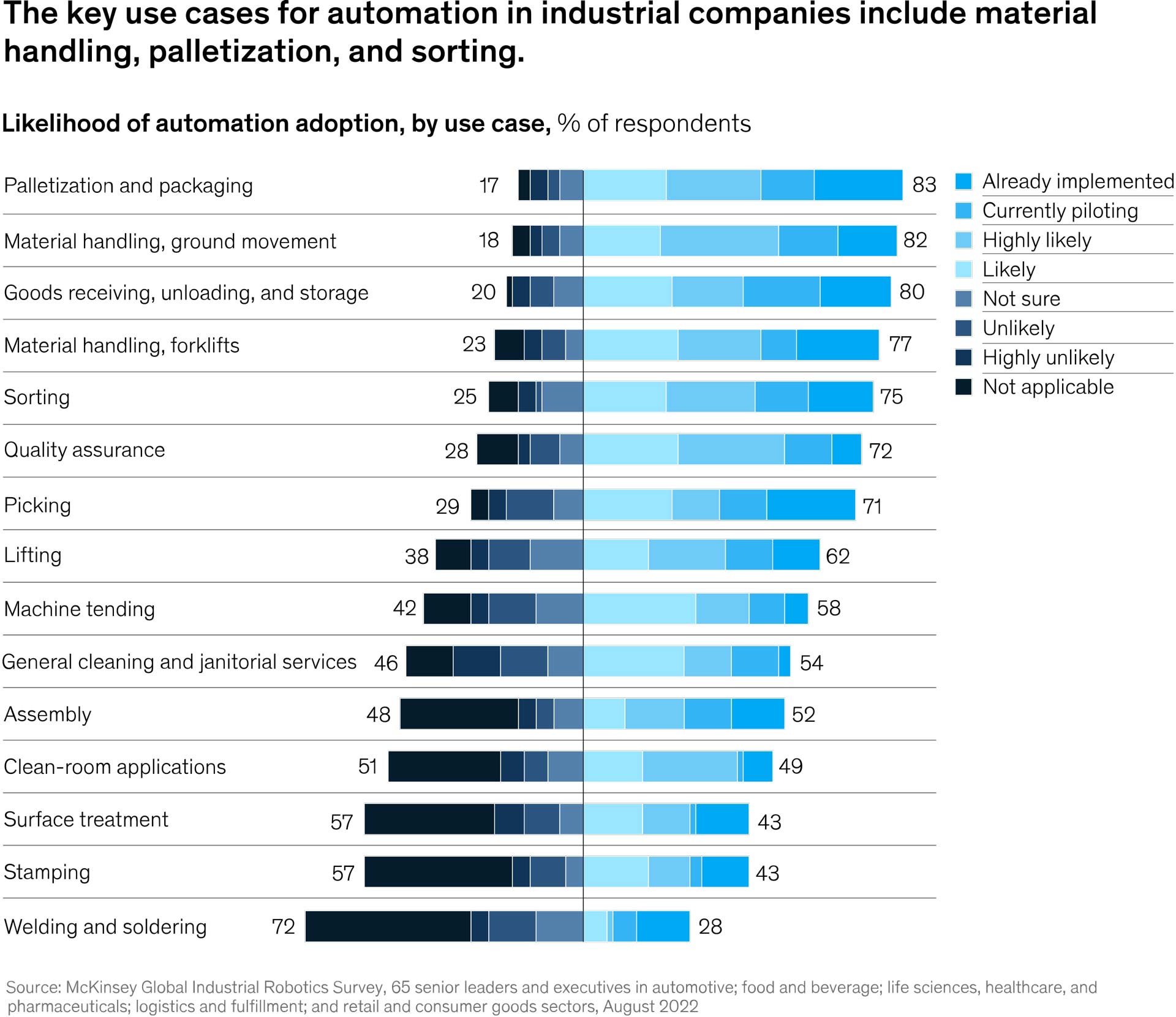

2. Material Handling, Palletisation and Sorting

Respondents were asked which tasks were likely to be automated in the short-to-medium term. For many companies, material handling via forklifts, picking and packing are already automated to some extent. In contrast, the tasks that are most likely to be automated in the coming years include material handling (ground movement), quality assurance, and palletisation.

Guidance Automation provides AMRs that can support materials handling automation, including conveyance and lifting. To see how AMRs can support sorting incoming deliveries, view this one-page AMR guide.

AMRs can also support palletisation, with the OTTO 1500 designed to safely move heavy payloads faster than any AMR on the market.

Automating picking and packing processes is made easy with our light-directed material handling systems, which use illuminated indicators to guide operatives to the right SKUs, reducing picking errors.

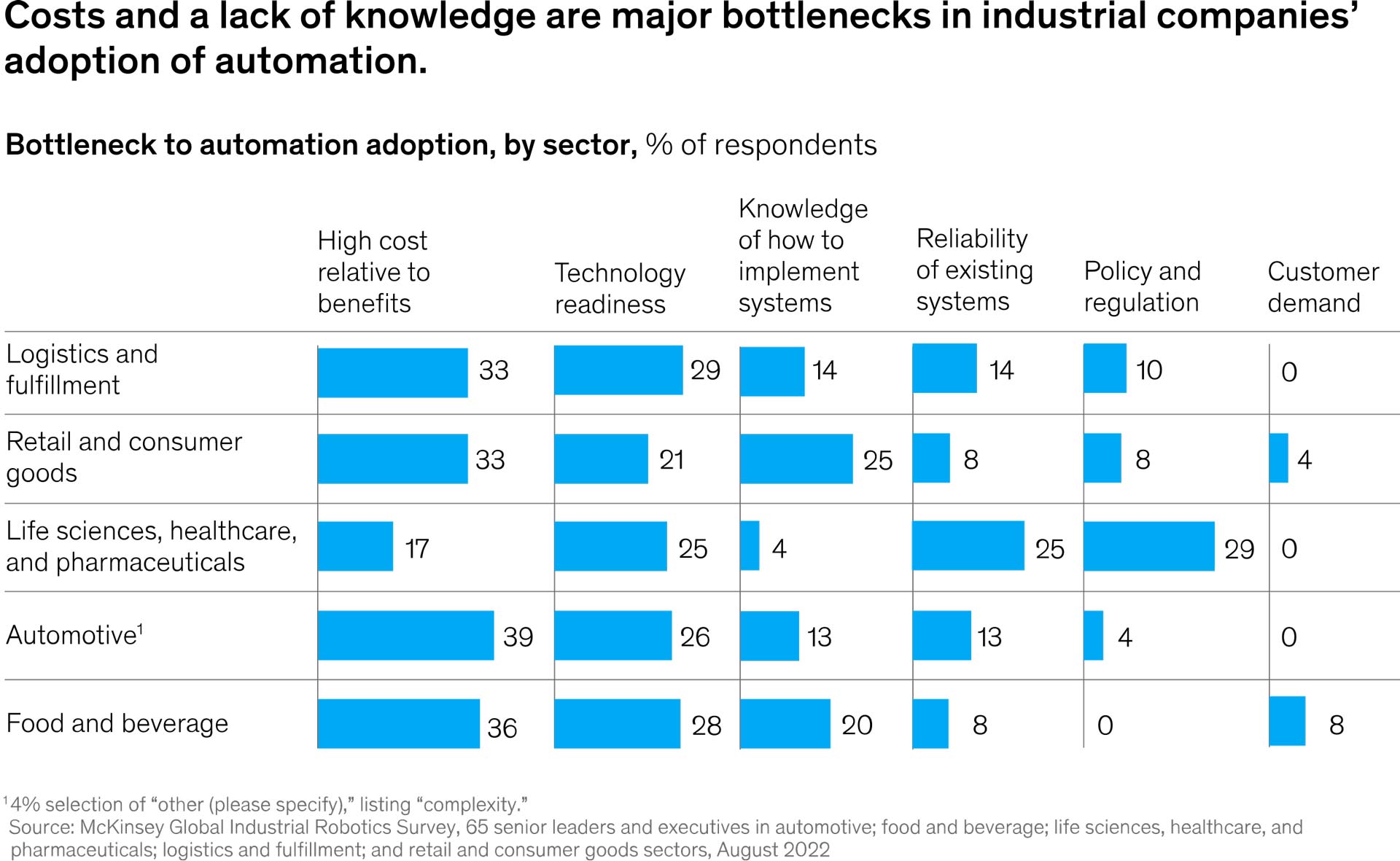

3. Major Barriers Include Costs and a Lack Of Knowledge

In most industrial sectors, the high cost of automation outweighs the benefits for at least a third of respondents, with the exception of Life sciences, healthcare and pharmaceuticals (17%). This sector instead indicated that policy and regulation were likely to create bottlenecks, as their products are more tightly regulated than others.

Interestingly, a quarter of respondents in the retail and consumer goods sector, those likely to invest the most in the coming years, felt that knowledge of how to implement systems would be a barrier.

This is an important point for us and we are continuing to create educational resources that clarify the automation process for business leaders so that they can approach these investments with confidence. We have an array of automation resources on our website, but if you can’t find the answers you’re looking for, let us know. As automation experts, we are always happy to have a conversation about how implementing robotics works for any business.

4. A Preference for Flexible Automation Provision

When asked about models of maintenance and servicing for automation and robotics, 55% of respondents said they would choose a system integrator that provides hardware and software maintenance and acts as a single point of contact.

We agree that a flexible and scalable automation service can support our customers to build confidence when it comes to robotics. Businesses can start with as little as a single robot or jump in with a whole fleet. Our goal is to implement flexible, accessible automation without needless disruption to operations. That is why we at Guidance Automation offer bespoke automation technology to suit the individual needs of each business.

We also provide ongoing support, tailored training and long-term maintenance for your custom automation solutions.

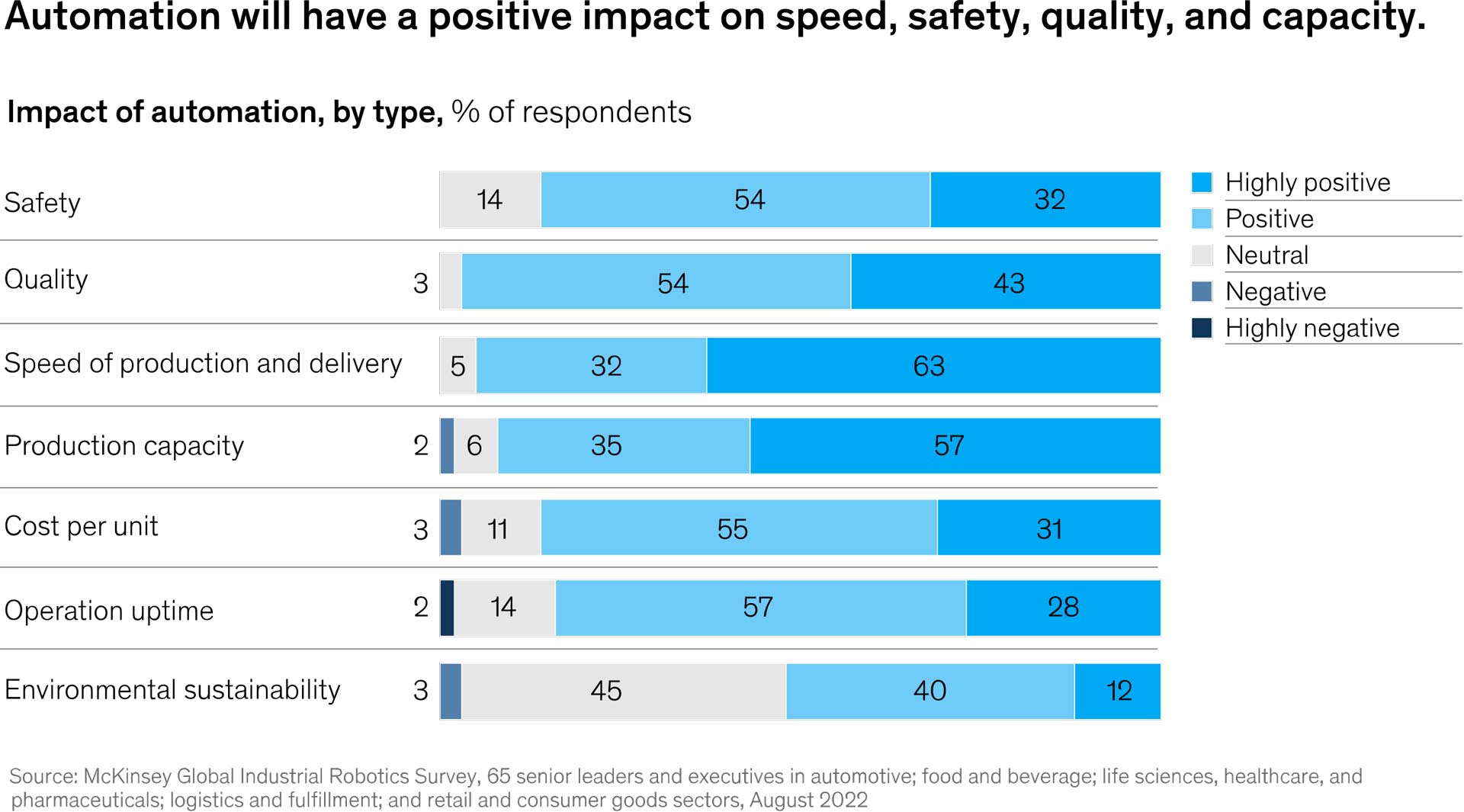

5. Quality, Production Speed and Capacity are the Top Reasons to Automate

Of the expected benefits, many industrial companies are looking forward to positive impacts such as speed of production and delivery, improved quality and increased production capacity. Safety is also seen as a positive impact for 86% of respondents, and other benefits include impacts on costs, operational uptime and safety.

In every industry, manual handling is a key cause of workplace injuries, with many causing damage to the back. These injuries lose companies valuable time with operatives off sick, not to mention legal fees which may be incurred. With autonomous material handling and robotics taking on some of these tasks, the risks of workplace injuries are drastically reduced.

Guidance Automation supplies autonomous material handling equipment or AMRs, which convey goods and materials around facilities automatically. While some may assume these could be dangerous, this is not the case. OTTO AMRs are equipped with safety sensors and LiDARs, so they can navigate around people and obstacles easily.

Robotic Automation as a Service with Guidance Automation

When we provide robotic automation solutions to businesses, we offer much more than an off-the-shelf product. We work with our customers in the long term to design a bespoke solution and implement automation processes, gradually optimising and tweaking to maximise efficiency and return on investment. Each implementation is unique because each business is unique, so we make sure our solutions are customisable and scalable.

Contact Guidance Automation today and ask about material handling solutions for your business.

Call us on: 0116 243 6250