Supply Chain and Logistics Automation: Overcoming Roadblocks

In a market with high demand and high labour costs, businesses in the UK logistics sector are at a key moment for logistics automation. Consumers have adopted online shopping more than any other European nation, with consumer eCommerce making up 30% of the total retail market in 2022. This is great for eCommerce companies, but for logistics providers, it produces a problem.

Consumers expect fast delivery of almost any and every product, putting pressure on delivery and fulfilment businesses to provide a competitive price for their customers, or risk being replaced by the internal logistics infrastructure of eCommerce giants. As Amazon’s use of robotics and emerging technologies shows, logistics automation is a key strategy for companies looking to maintain their share of the market.

Investing in automation can enable logistics companies to deliver faster and more efficiently by improving both digital and physical processes. But how can they achieve this? In this article, we explore why logistics automation seems hard and offer some tried and tested solutions that can make automation accessible for all.

Logistics Automation in the UK

Precedence Research forecasts that the global logistics automation market size will hit USD 162.5 billion by 2030, more than tripling where it stood in 2021. With a high volume of eCommerce orders and high labour costs compared to the rest of Europe, the UK is a prime candidate for logistics automation. With the right solutions, logistics companies that automate will be a step ahead of the competition, improving their efficiency and building vital capacity.

Why logistics companies may hesitate to automate

However, logistics companies struggling with poor personnel retention and high salary expectations may wonder how they are supposed to invest in automation. According to research by McKinsey & Company, a logistics company may hold back from investing in automation technologies for several intersecting reasons.

However, logistics companies struggling with poor personnel retention and high salary expectations may wonder how they are supposed to invest in automation. According to research by McKinsey & Company, a logistics company may hold back from investing in automation technologies for several intersecting reasons.

Competition

Many logistics companies keep their prices low to maintain their share of e-commerce delivery opportunities against increasing competition. This may mean returns are too low to justify investment in buying automation outright.

Seasonal Demand Shifts

Similarly, demand for deliveries can shift dramatically across the course of a few months, for example, spiking around Christmas and Black Friday deliveries. Companies may fear that investing in enough automation to handle these peaks well would leave them with significant spare capacity for most of the year.

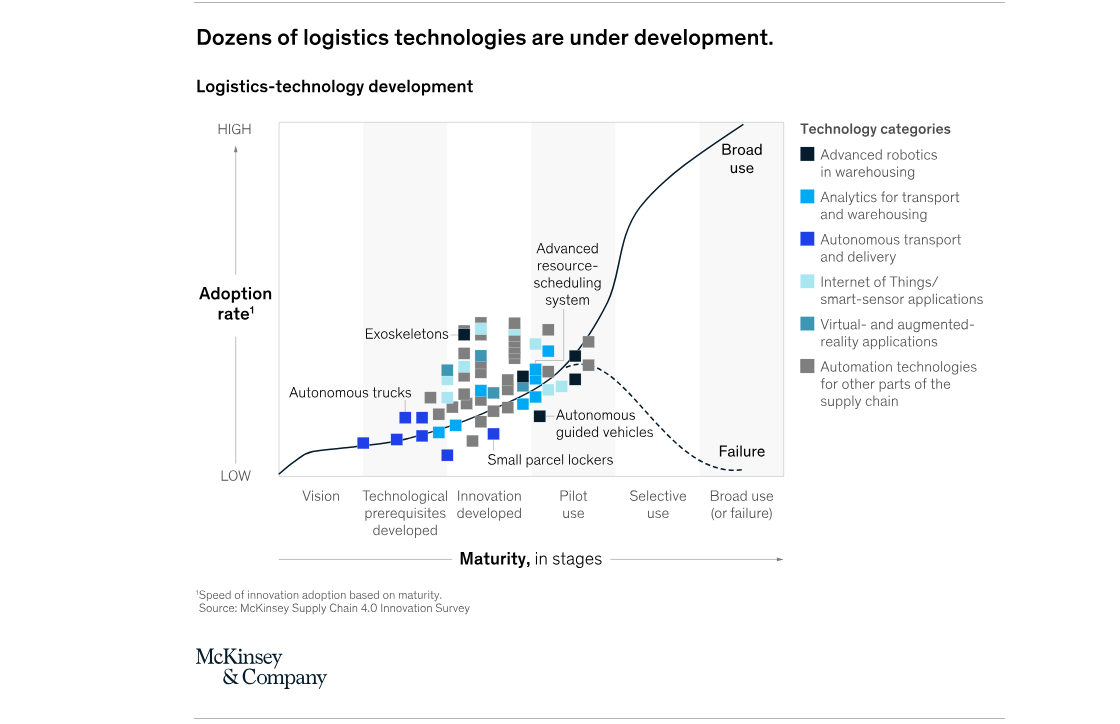

Technology Bubbles

McKinsey found that more than 50 types of automation technologies are in development for supply chain automation, but none have been widely adopted. Uncertainty about which technology will take off and create a strong ROI is causing hesitation, as many new technologies may become obsolete in a few years.

Waiting Lists

Even after getting enough capital together to invest, choosing a solution and planning for demand shifts, logistics companies may run into another obstacle. Supply chain automation manufacturers may not be able to meet the demand for hardware. The research found that ‘manufacturers operating at full capacity cannot even provide [companies] with quotes.’

Rapid Change Breeds Uncertainty

While customers continue to expect faster delivery times, supply chains and distribution networks across markets are shifting towards omnichannel systems, catering to home delivery, in-store collection and customer locker systems.

The complexity of designing these shifts is creating uncertainty around where and how to automate processes in a new system.

A Turning Point for the Logistics Sector

Many small logistics companies are struggling to maintain consistent workflows, particularly as contracts are typically short enough that future demand is unpredictable even three years ahead. This can make it difficult to justify large capital investments where the capacity added may not be used a few years down the line.

However, where automation in large companies is typically a capital investment, SMEs can benefit from a more flexible model. Robots-as-a-Service, or Robotics-as-a-Service (RaaS), is a model which can help overcome many of the obstacles logistics businesses are facing today.

Automation Consultants: How We Can Help

At Guidance Automation, we provide advice and solutions for companies searching for cost-effective automation. This is why we offer guidance on a case-by-case basis, getting to know each of our customers and their business needs. We recommend solutions and strategies that can build capacity in their existing systems, without risking large amounts of capital or refitting whole facilities.

Low Initial Investment

With a RaaS model, the cost of automation shifts from upfront costs to a licence for use. This means that instead of owning a hardware solution, the company engages our services to achieve an outcome. The process looks similar: robotics and automation in your facility, providing efficiency and capacity when you need it. The difference is that costs are lower, spread over time, and more flexible than outright purchases.

Scalable for Seasonal Peaks

Evidence suggests that business leaders are reluctant to invest in something they will only use at certain times, and this is a savvy move. There is no incentive to spend on infrastructure that will be dormant for most of the year. With this in mind, there are clear benefits to RaaS models. At peak times, logistics companies can hire additional Autonomous Mobile Robots (AMRs), for example, to increase capacity. When the rush is over, the extra equipment is returned, with no overhead budget wasted.

Tried and Tested Solutions

Autonomous Mobile Robots and Light-directed Picking technology are two of the most developed physical automation solutions for warehouses and logistics. There are plenty of case studies that show the benefits of the solutions we can provide. We are confident that these technologies are here to stay, and the autonomous material handling market is only going to grow.

High Stock Availability

While larger companies may have reached capacity, automation providers with more bespoke offerings are underutilised. At Guidance Automation, we work with our partners to manage demand and supply, ensuring our clients can always access up-to-date automation technology and software when they need it.

Bespoke Automation and Ease of Reprogramming

All businesses are different, and providing a one-size-fits-all automation approach leads to wasted budget and inefficiencies, defeating the object of smart automation. As opposed to off-the-shelf products, purpose-built solutions ensure companies avoid compromising and gain technology that supports their model, integrates with current processes and is easy to modify.

Our bespoke AMR tops and modules, for example, include carts that robots can move around, conveyor toppers and robotic arms. These solutions can help create the perfect automation solution for an individual business

This custom approach means logistics companies can access automation without interrupting processes, rearranging facilities or overspending on unnecessary equipment.

Smart Automation for Logistics Companies

If you’re looking to simplify your automation investment, we would love to advise on the use of robotics, warehouse management systems and other automation solutions. We can bring equipment to your facilities so that you and your stakeholders can see first-hand how these solutions would fit with existing systems and minimise the cost of logistics automation.

The barriers to automation are falling away, and the more pressure on the logistics sector, the more urgent the need for automation becomes. Increasing capacity and improving efficiency is no longer out of reach for SMEs, with our Robotics-as-a-Service model providing the scalable and flexible automation needed to maximise investment and achieve a quick ROI.

Read more about our Automation Solutions

Autonomous Material Transportation

Robotic vehicles move goods and materials from A to B, minimising unproductive travel for human operatives. Various top modules are available or can be bespoke to your requirements. Autonomous Mobile Robots (AMRs) come in different sizes depending on the max payload. Our largest AMR can carry up to 1900kg.

Read more about Autonomous Material transportation…

Light-Directed Material Handling

Use of an automated light-direction system on storage walls, racks, and mobile robot tops to improve your picking speed and accuracy.

Read more about Pick-to-Light and Put-to-Light

Warehouse Execution and Control Systems

Our WECS system, NEXUS, can be used to integrate and centralise control (and collect data from) all the technologies around the warehouse or facility. The WECS covers Autonomous Mobile Robots, light-directed material handling systems, conveyors, sorters, robotic arms, and many other warehouse automation technologies.

Automation Consultation

Guidance Automation would be delighted to speak to you about automation options for your business. We specialise in providing automation solutions tailored to the warehousing, logistics and distribution, eCommerce, and manufacturing sectors.

We offer a free, no-obligation survey to companies of all sizes.

If you are an SME, we even offer a free autonomous mobile robot trial to demonstrate how such vehicles could operate in your environment with your people.

Start your Digital Transformation Journey with Guidance Automation today:

Email us at: enquiries@guidanceautomation.com

Fill out the form on our Contact Page